Wire Rope Sling

Wire rope slings are critical lifting devices used in construction, manufacturing, and maritime industries for hoisting and rigging heavy loads. Below are the specifications and features of wire rope slings:

Specifications

Material

Usually made of high carbon steel, stainless steel, or galvanized steel. Wire ropes are constructed of multiple strands of wire twisted into a helix.

Construction Types

6x19, 6x36, or 8x19 class constructions are common. Example: "6x36 IWRC" = 6 strands with 36 wires per strand, Independent Wire Rope Core.

Core Types

IWRC (Independent Wire Rope Core) – stronger and more crush-resistant. FC (Fiber Core) – more flexible but lower strength.

Diameter Range

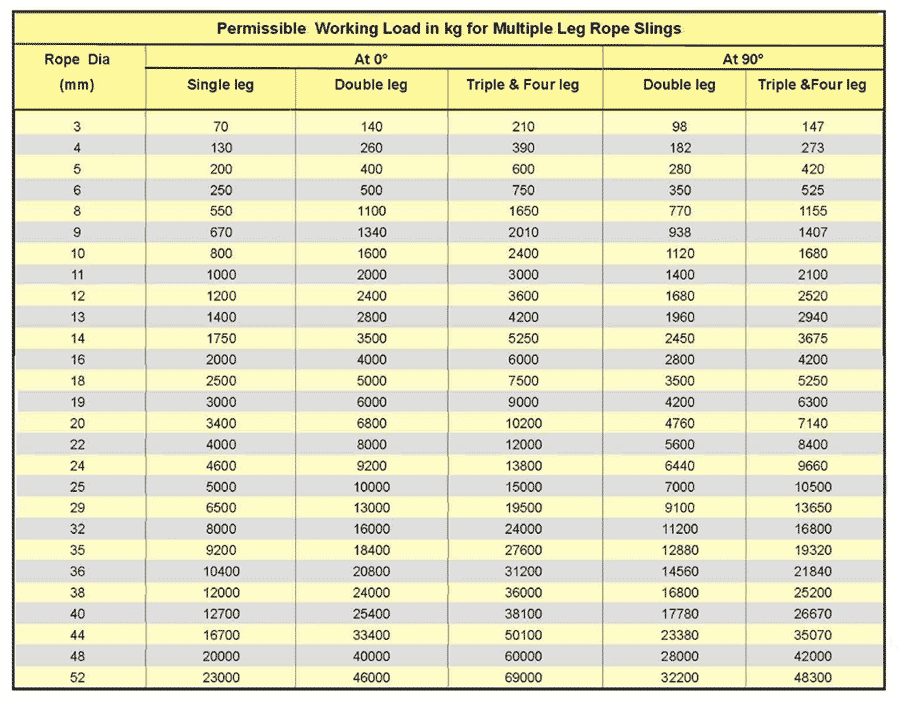

Typically ranges from 1/4 inch to 2 inches or more. Rated Capacity (WLL - Working Load Limit): Depends on rope diameter, configuration, and angle of lift. Must comply with standards (ASME B30.9, OSHA 1910.184).

Length

Customizable as per application – from a few feet to dozens of feet.

End Fittings

Thimbles, hooks, eyes, shackles, or spliced loops.

Finish

Bright (bare steel), galvanized (zinc-coated), or stainless for corrosion resistance.

Key Features

High Strength-to-Weight Ratio

Efficient for heavy-duty lifting with manageable weight.

Durability

Resistant to abrasion, crushing, and high temperatures (compared to synthetic slings).

Versatility

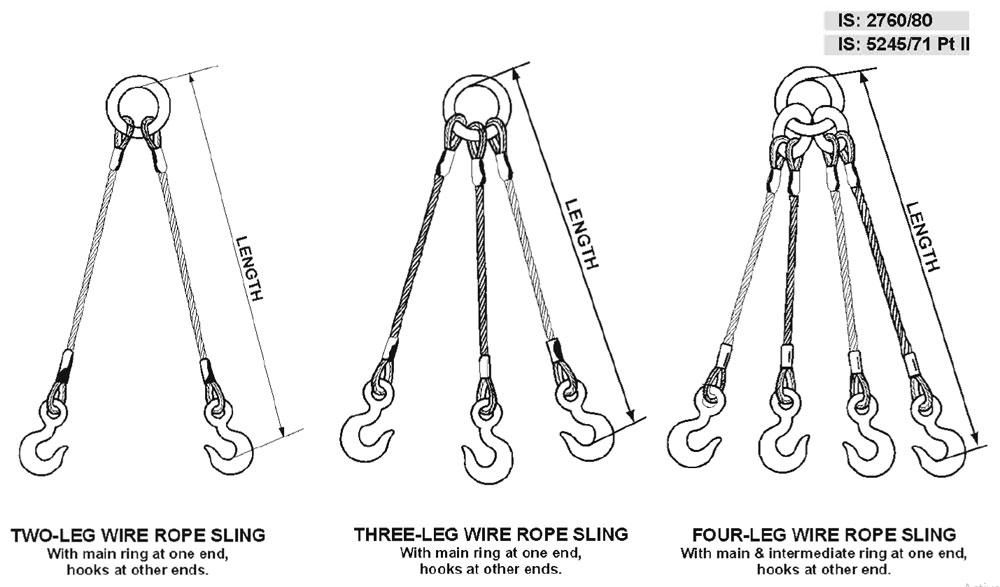

Can be configured in multiple sling types: single leg, multi-leg, choker, basket, and eye-and-eye slings.

Flexibility

More flexible than chain slings, useful around irregular loads.

Cost-Effective

Long-lasting and relatively low maintenance compared to synthetic alternatives.

Inspection & Safety

Easily inspected for broken wires, kinks, or corrosion. Must be removed from service if damaged per OSHA/ASME guidelines.